Kalrez® Parts Reduce Wafer Contamination

Artikel

Kalrez® FFKM Seals Help Minimize Wafer Process Contamination

Perfluoroelastomers (FFKMs) are used as seals on wafer processing equipment due to their extraordinary resistance to chemicals, including reactive plasmas and extreme heat as high as 327°C. FFKM performance can vary depending upon the chemical composition. Specially formulated Kalrez® products may be required to help reduce wafer contamination.

Low Outgassing Properties of Typical FFKM

Weight Loss / Particle Generation

Fabricators have found that plasma is a very powerful tool for etching, CVD and stripping because all materials are consumed. FFKM seals are used in these processes because of their exceptional resistance to aggressive media. Prolonged exposure to plasmas can degrade seal surfaces resulting in particulate contamination even before sealing functionality is lost. The ideal seal, therefore, would resist surface degradation while maintaining sealing functionality.FFKM seals are designed to with stand chemical attack and provide extended seal life. They exhibit low weight lossand particle generation, thus improving wafer yield,increasing process reliability and reducing frequency of equipment maintenance. See the relative particle generation in plasma for four FFKM compounds.

Metallic Extractables of FFKM

Outgassing/Sealing Functionality

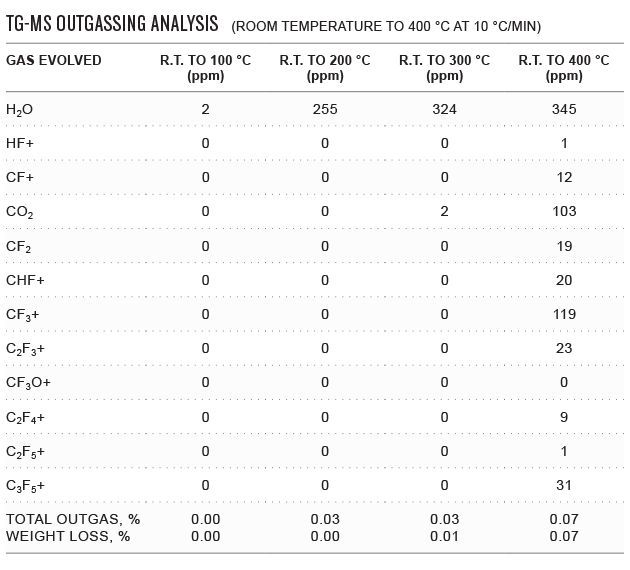

High heat and temperature spikes can “cook” elastomeric seals causing them to become hard and brittle. When this occurs, their crosslink structure, the key to elasticity, becomes irreversibly damaged making effective sealing impossible. Elastomers can also degrade under high temperatures, causing outgassing to occur, thereby contaminating the process environment. Thermal processes like oxidation and diffusion need seals that resist not only the process chemicals, but also the extreme temperatures required. Reliable, in-service temperature ratings for sealing materials are best defined by long-term (672 hour) testing for seal force retention. See extremely low outgassing properties of a typical FFKM compound from room temperature up to 400°C.

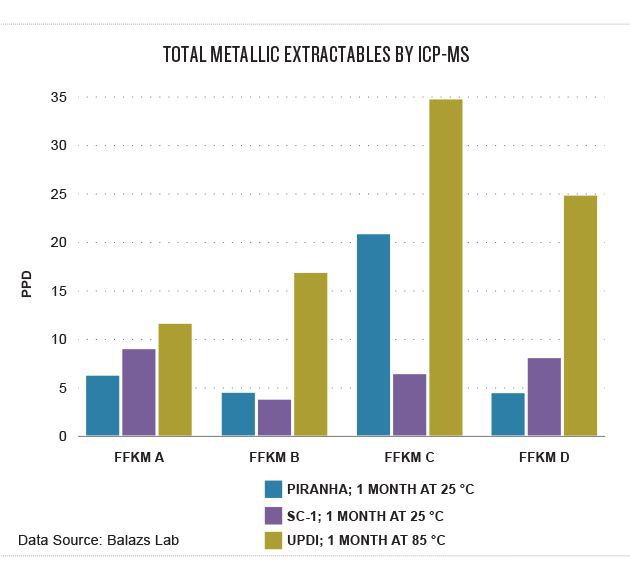

Metallic, Ionic And TOC Extractables

To transform raw semiconducting materials into useful devices, aggressive acids, solvents (including amines), and bases are used. These chemicals can attack elastomeric seals causing them to swell and degrade or leach undesirable metallic and ionic extractables. This may cause wafer contamination and subsequently integrated circuit functionality.

FFKM seals are used in wafer cleaning, wet etching, and photolithography. Specially-designed FFKM compoundsfeature low levels of metallic, ionic and TOC extractables as well as excellent chemical resistance. See the extractables performance of several FFKM compounds after 1 month in UPDI water, piranha and SC1.